Mesh2NURBS#

Presented: Group Meeting, Zuse Institute Berlin, February 2016 Collaborators: T. Amiranashvili, M. Bindernagel, H. Lamecker, H. Ramm Institutions: Zuse Institute Berlin (ZIB) — Computational Medicine Group · 1000 Shapes (ZIB spin-off)

The Problem#

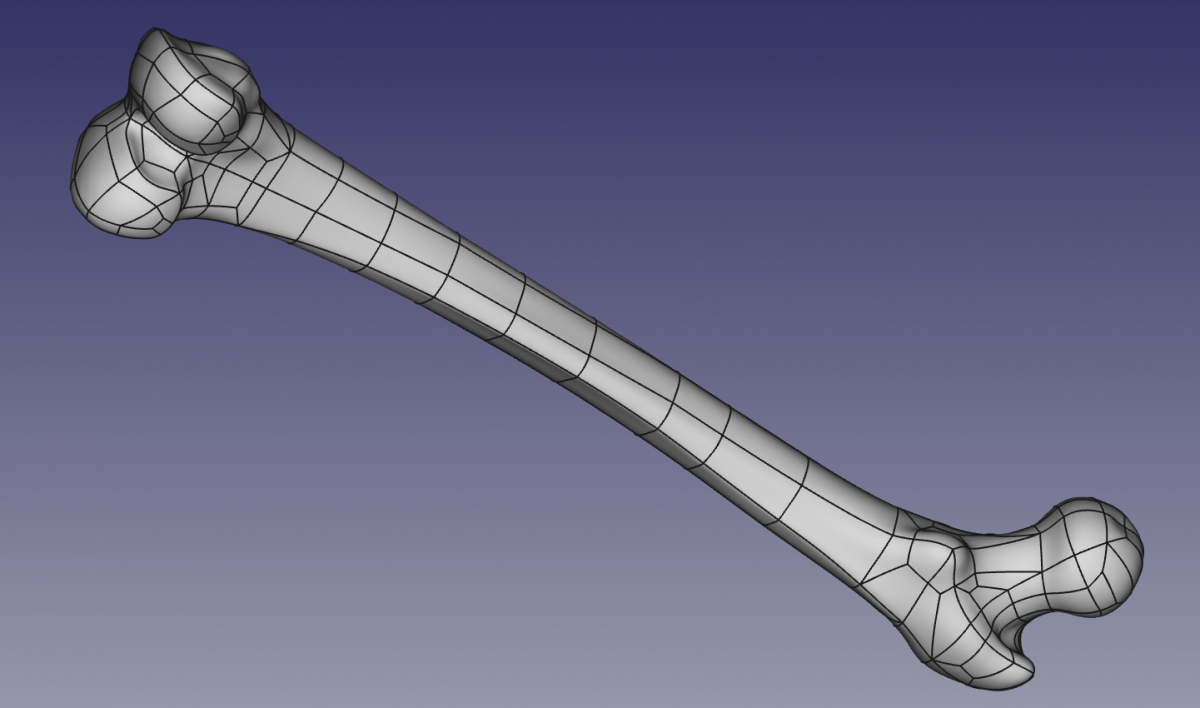

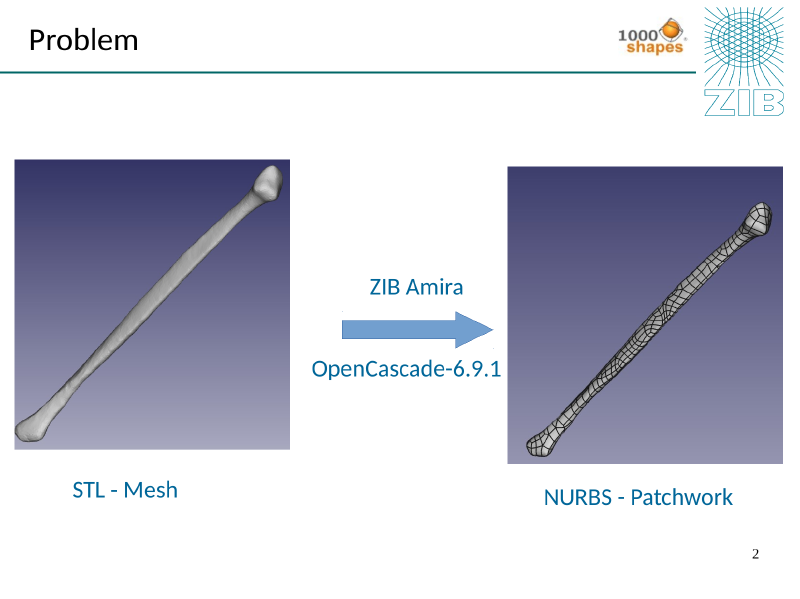

Modern medical imaging (CT, MRI) produces detailed 3D surface meshes of anatomical structures. CAD systems used for designing implants and surgical instruments, however, require smooth parametric surfaces — specifically NURBS (Non-Uniform Rational B-Splines). Bridging this gap automatically and accurately is a fundamental challenge in patient-specific medical device manufacturing.

A triangulated STL mesh from a CT scan — for example a long bone — must become a structured NURBS surface suitable for CAD tools and biomechanical simulation. The challenge is making this conversion automatic, accurate, and topologically valid.

Why NURBS?#

NURBS surfaces are the standard representation in medical CAD for several reasons:

- Simulation-ready — naturally support deformation modelling of living tissue, effects of drugs on organs, and interaction with surgical devices

- Implant design — provide a smooth, controllable substrate for designing patient-specific artificial implants

- Surgical device integration — enable simulation of anatomical structures interacting with instruments and diagnostic tools

- Compact — significantly smaller file sizes than equivalent STL meshes

Approach#

The project was a feasibility study exploring automated conversion of triangulated surface meshes into smooth NURBS surfaces. The core insight is that NURBS surfaces require a quadrilateral topology as their foundation — they cannot directly fit over triangular meshes.

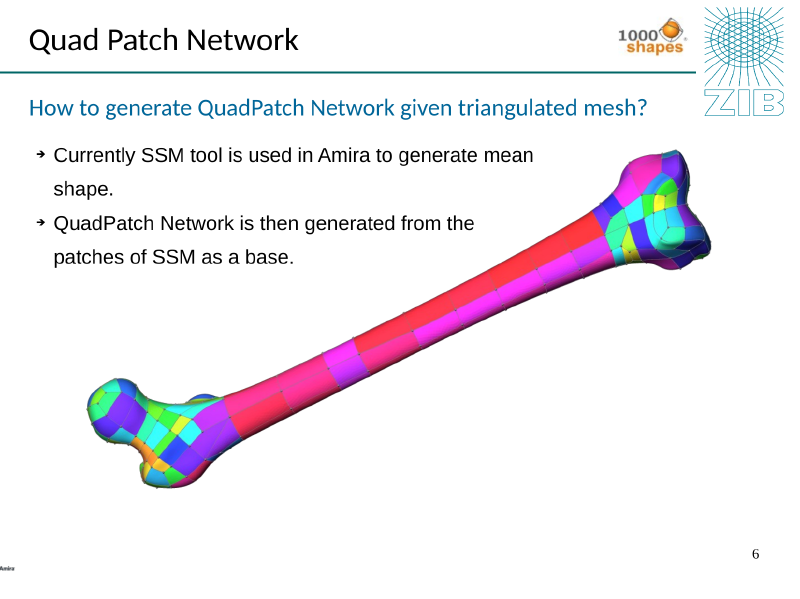

The approach proceeds in three conceptual stages:

- Deriving a quadrilateral patch network from the input triangulated mesh

- Fitting a smooth NURBS surface patch to each quad region

- Stitching the individual patches into a coherent, watertight surface approximation

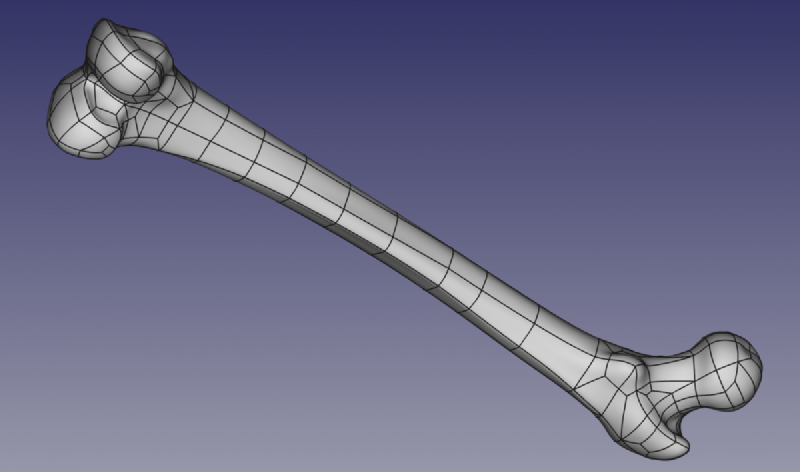

Result#

The prototype demonstrated that automatic mesh-to-NURBS conversion is feasible for anatomical geometry. The resulting surfaces are smooth, compact, and compatible with standard CAD workflows for medical device design.

Relevance#

This work connects directly to later roles:

- Ottobock — NURBS surface approximation for prosthetic socket fitting, where the same mesh-to-smooth-surface challenge appeared in a clinical production workflow

- Fiagon — 3D surface processing for surgical navigation, where accurate registration between patient anatomy and device geometry required the same geometric foundations

The core problem — bridging discrete geometry and smooth CAD representations — recurs throughout computational medicine, medical device engineering, and orthotics.

Domain: Medical technology · Computational geometry · CAD/CAGD · NURBS surface fitting

Institutions: Zuse Institute Berlin · 1000 Shapes